SS-PREP®12Cr9NiAlMo Prealloy Spherical Powder

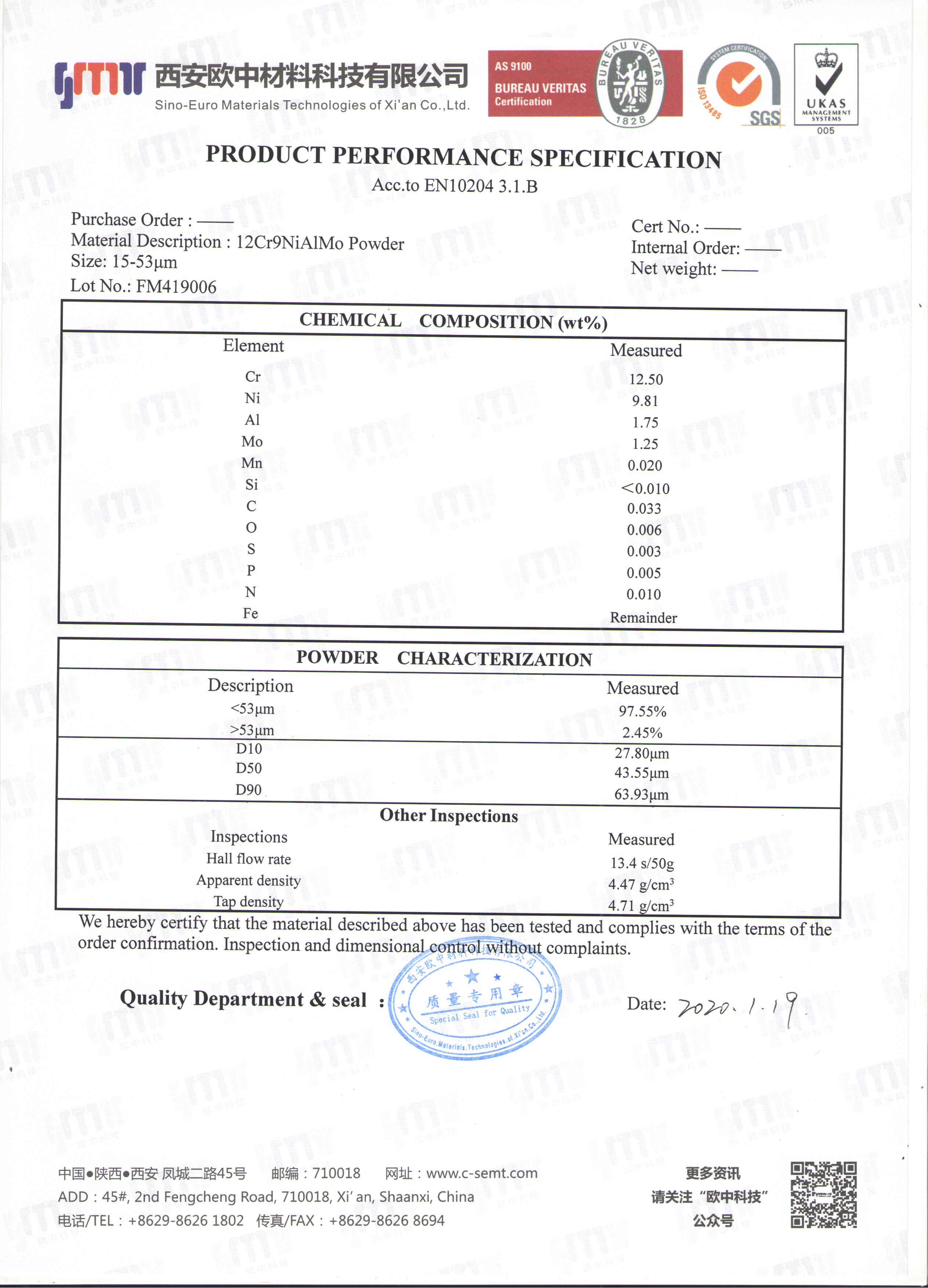

Recently, Sino-Euro has prepared 12Cr9NiAlMo prealloy spherical powder also known as CX steel. Fig. 1 displays the properties and chemistry of 12Cr9NiAlMo powder. For 15-53μm powder, Hall flow speed with 2.5mm calibrated orifice is 13.4s/50g, and apparent density is 4.47g/cm3.

Fig. 1 12Cr9NiAlMo 15-53μm COA

The excellent corrosion resistance and mechanical properties of the 12Cr9NiAlMoprealloy makes itself has high application value.

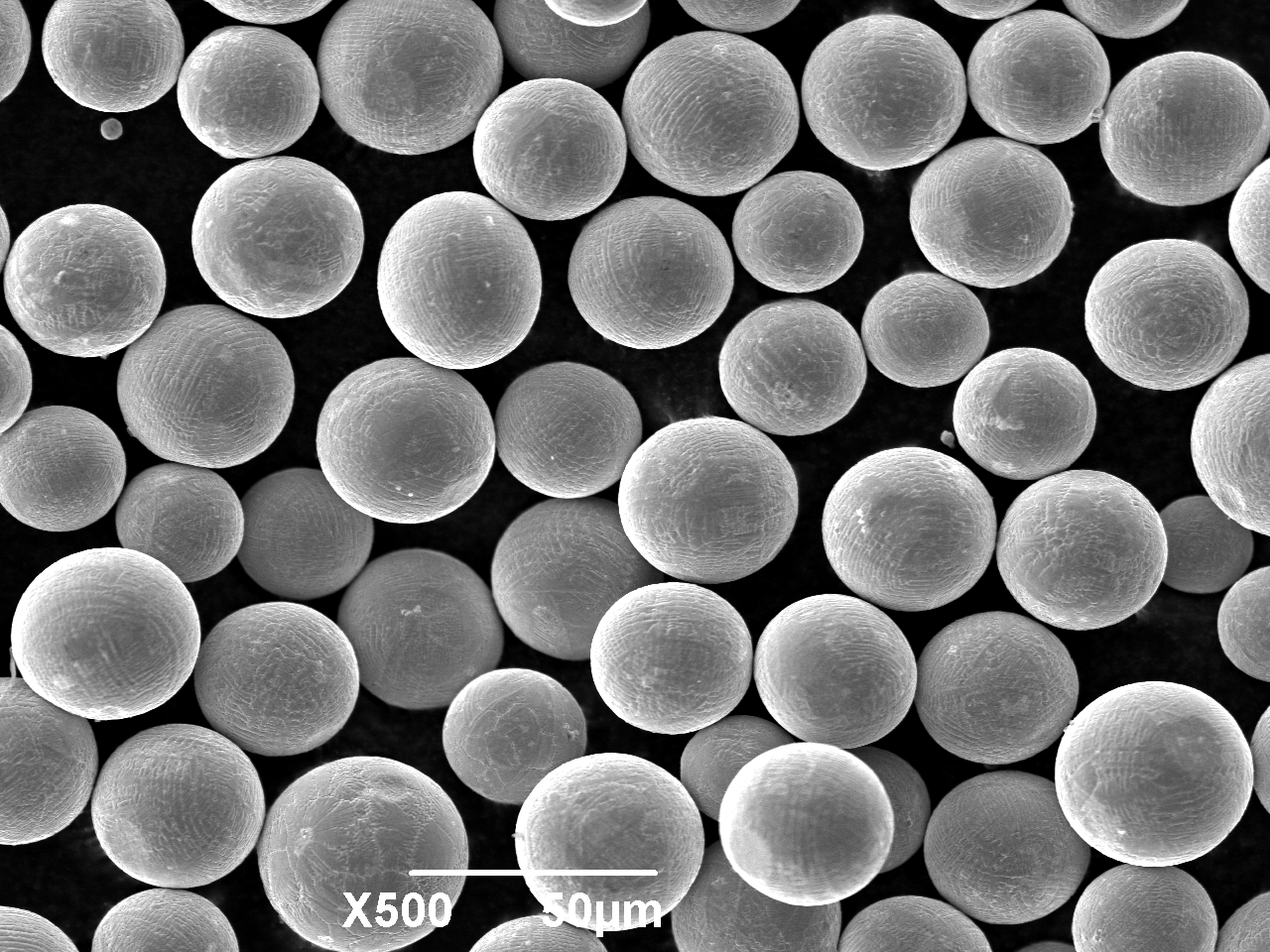

The morphology as shown below:

According to the research of AM center in Canadian New Brunswick University, the chemical content of CX powder used in SLM process is shown in Table1:

Table1. chemical content of CX powder

Element | Fe | Cr | Ni | Mo | Al | Mn | Si | C |

Weight(%) | Balance | 11-13 | 8.4-10 | 1.1-1.7 | 1.2-2 | 0.40 | 0.40 | 0.05 |

According to the research, using the parameters in table2, the Hardness of the printed component could reach 35±1HRC,Yield strength is 1036MPa and Elongation is 21.7%。

Table2:printing parameter of CX powder

Laser type | Laser power(W) | Scanning speed (mm/s) | Hatching Distance(µm) | Layer thickness (µm) |

Yb-fibre | 258.7 | 1066.7 | 100 | 30 |

Table3:the mechanical properties of CX component

Yield strength (MPa) | Young's modulus (GPa) | Ultimate tensile Strength (MPa) | Elongation(%) |

1036 | 153 | 1113 | 21.7 |

The paper “Microstructure and mechanical properties of stainless steel CX manufactured by Direct Metal Laser Sintering” was published in Materials Science & Engineering A journal。

Sino-Euro Materials Technologies of Xi’an Co., Ltd.(Sino-Euro) is a subsidiary company of NIN Group(www.c-nin.com). The capital investment is about 15 million US dollars. Sino-Euro is specialized in powder metallurgy, Prealloy Spherical SS-PREP® Powder, Additive Manufacturing Wire, Bar & Substrate, and HIP service & components. Sino-Euro has been authorized with AS9100D, ISO9001 and ISO13485 Quality Management System.

Navigation

Follow Us